ProCommander™ III is a wired communication system designed to provide full-duplex communication in potentially harmful/hazardous environments, such as may be found in Nuclear Power Station Reactor Vaults and environmentally-controlled laboratories. The system supports up to 192 headsets.

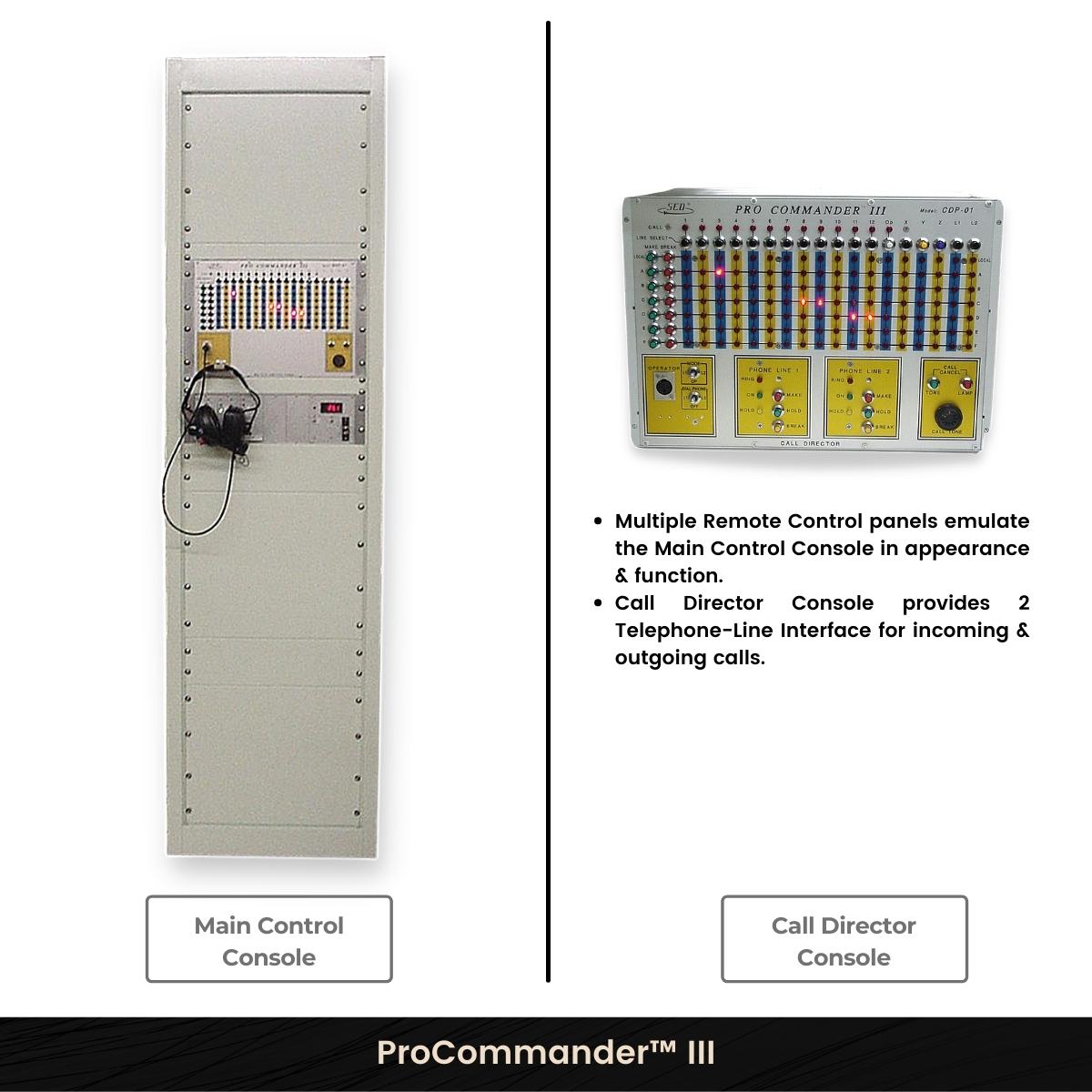

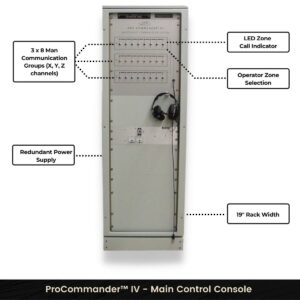

The Main Control Console provides conferencing for the 12 Zones, 2 telephone lines, and 3 Maintenance Communication Groups (through the ProCommander™ IV) as well as provides inputs from PA and alarm systems. The Call Director provides a connection for calls from the telephone lines and remotely controls the Main Control Console.

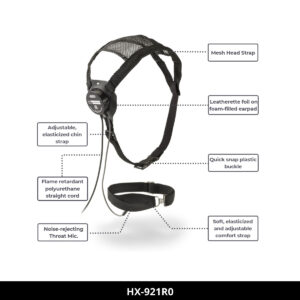

Depressing the Call Button on any Headset signals the Attendant/Operator. Typically, the worker puts on a SED Headset, dons the Plastic Suit, plugs themselves into the SED Combined Air/Communication Hose™ and then plugs their hose into a Breathing Air Station which provides 4 jacks into the communication system.

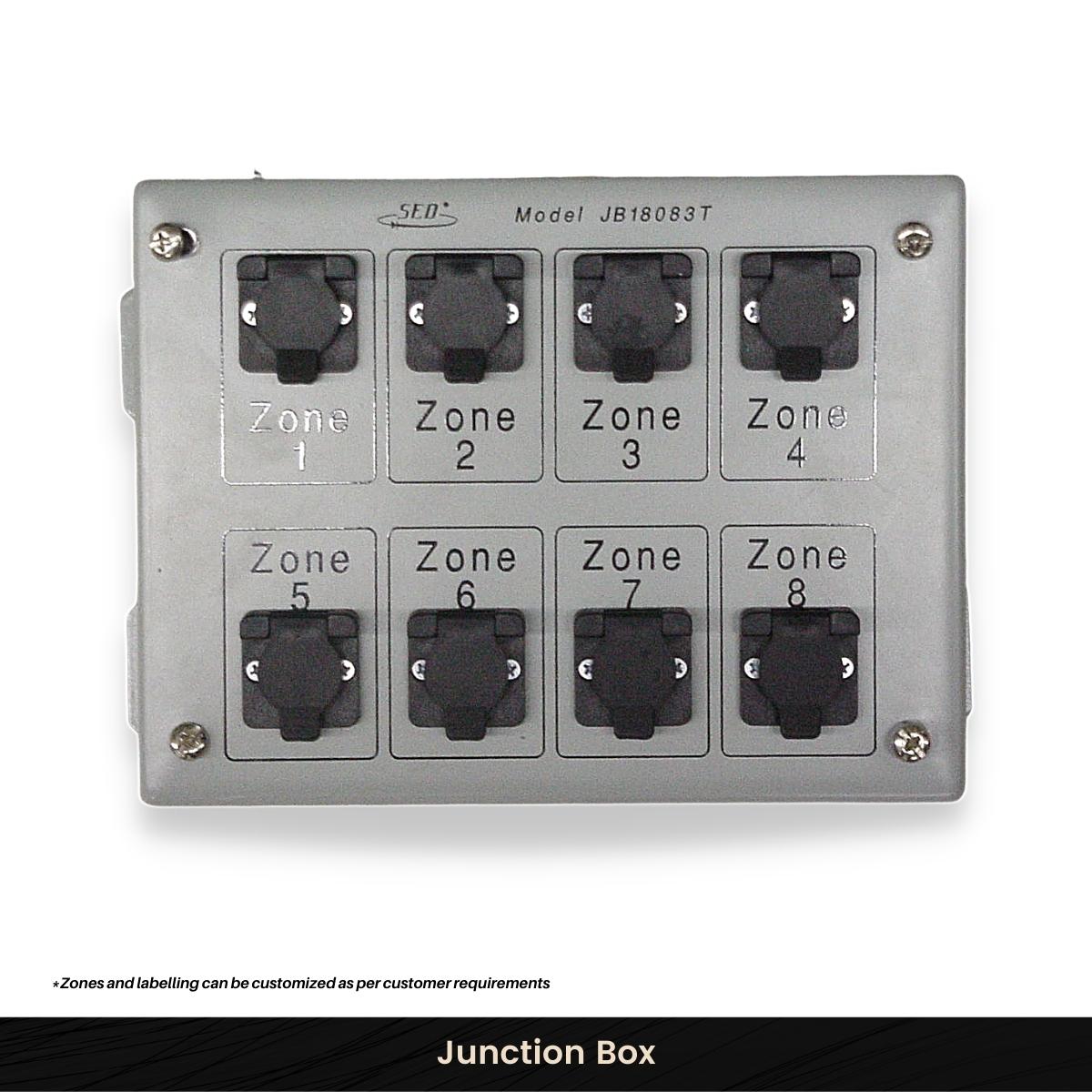

Workgroups may include up to 16 Users per Zone which can be interconnected with other groups through the Conferencing Panel. The system can be tied directly to two telephone lines and ensures that employees working in Plastic Suits have clear communications, don’t miss any critical PA announcements and evacuation alarms. Workers using the ProCommander™ III can also coordinate with workers that are using the Maintenance Communication System (ProCommander™ IV) where up to three other trade-specific groups may be conferenced.

All circuitry is contained within the belt-mounted Headset interfaces. All wiring for the same Zone and line may be daisy-chained to reduce system wiring costs. All lines and amplifiers are short-proof, which means you never need to replace fuses. The central redundant power supply makes this system extremely reliable and affordable to operate. Originally designed for use in nuclear power stations where reliability is of critical importance, this system may be easily applied to any industrial communication application.