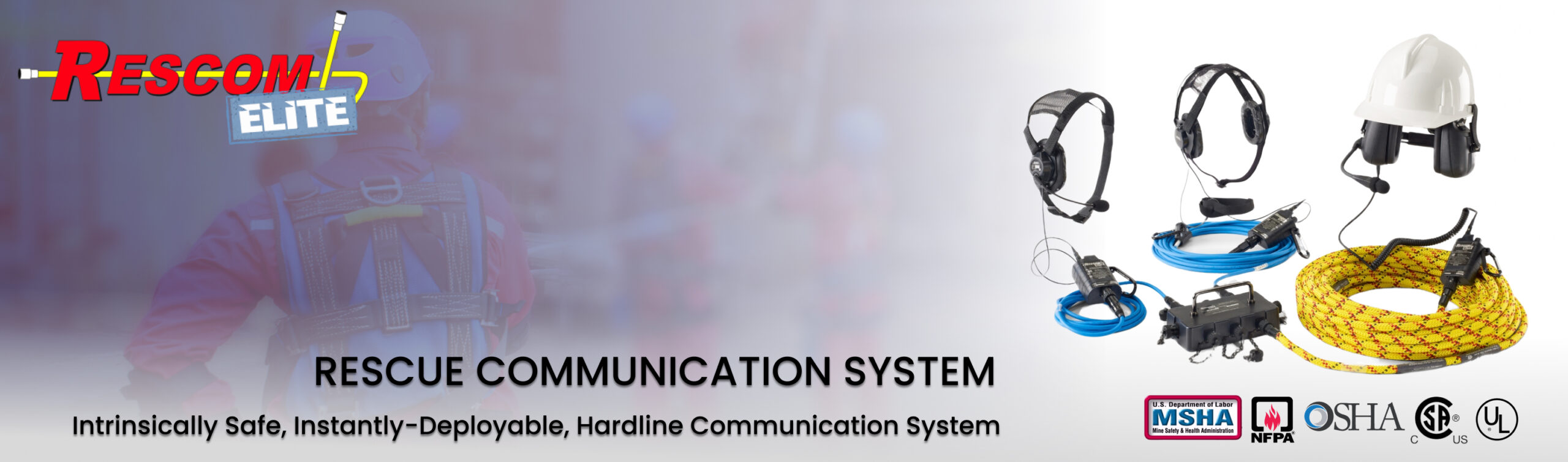

Rescom® Rope Care Instructions

- Tying two ropes together

If only two people are to be connected, a Safety/Communication™ Rope will be tied to each person’s safety harness and the unstressed rope end connectors connected to the headset/intercom termination. To join two lengths of rope, the ropes are first joined using the appropriate knot (as is normally used to tie 2 lengths of rope together) and then the electrical connection  is accomplished using a coupler (P/N C32D).

is accomplished using a coupler (P/N C32D).

The following is a list of commonly used knots that can be used with the Rescom Safety/Communication™ Rope:

- Bowline

- Butterfly

- Prussic Hitch

- Waterman’s Knot

- Half Hitch

Communications Rope connectors are military style with a noticeable “clicking when mated” mechanism to ensure a secure connection has been made.

- CARE AND MAINTENANCE

Regular care and maintenance of the Rope is important to get the longest life out of the rope.

Regular washes will assure that where possible dirt and sand that might otherwise work its way into the rope fibres, will be removed.

If allowed to migrate through the rope’s outer braid the granules could abrade the inner rope core fibres. Similarly, the earliest possible removal of chemicals from the rope is very important since they may have a deleterious effect on the rope core or jacket.

Cleaning of the rope may be accomplished with commercial rope cleaning equipment and mild detergents. However, if not available the rope may be soaked in a mild laundry detergent or a mild dish soap and then rinsed with clear water. To protect the connectors a Coupler (P/N: C32B or C32D) should be connected to the two ends of the rope to prevent debris from being transferred into the connectors.

After washing, hang the rope up to dry. The polyester rope may be used when it is wet – its strength will not be diminished. Note: The rope when wet will be much heavier.

- The RESCOM® Rope as Primary Lifeline

The RESCOM® Rope has a >40kN (>9000 lb.) tensile strength and as such (as long as it is used in the industry approved manner) may be used as a Primary Lifeline. Where the standards allow, it’s strength permits use as a two-man rope. (Ultimate breaking strength is 10,800 lbs)

The Rescom rope is NFPA certified and meets the requirements for Life Safety Rope of NFPA 1983:2017 Edition.

The RESCOM® Rope has the capacity to handle emergency situations when time is of the essence and its 1.27 cm (1/2″) diameter makes it easier to grasp and therefore to haul with it.

The RESCOM® rope may be used with mechanical advantage pulley systems and may be knotted as with any safety rope.

- Rope Inspection

A visual inspection must be performed by a competent person prior to each use to check for damage. If damage has occurred to the jacket, it may be in the form of fraying, nicks, cuts, abrasions, hard glazed areas (characterised by a glassy appearance on the surface), etc. of the braid. If damage has occurred to the rope core, damage may appear as a flattened, narrowed (hourglass shaped), wavy, or soft and mushy area.

Virtually all standards dealing with rescue and safety equipment require that a rope be tested and/or replaced if it has been shock loaded. If the Combined Safety/Communications™ rope has been used in a fall arrest situation – replace it: (it doesn’t owe you anything). Also, recall that even a seemingly minor shock load can generate tremendous loading on the rope.

As long as regular inspection parameters are met, the manufacturer “Special Electronics & Designs Inc” recommends replacement of rope every ten (10) years, as per NFPA recommendations.

- Descent Devices

By slowing descent, all approved Descenders do the job they are intended for, but some Descenders may cause more damage to the rope than others due to design differences such as sharper teeth or more sudden braking action. Please inquire with the Descender manufacturer of the effect their product will have on a safety polyester lifeline.

- RF (Radio Frequency) Radiation

Contrary to common commentary, the Rescom® Modular™ and Elite™ System DO NOT USE any type of radio transmitter in their assembly. It is not, as some sales organizations call it, a “radio rope”. All signals are sent as audio signals and are of a low signal level. It does not emit /radiate any radio frequency signal and therefore, cannot be overheard with another radio receiver.

The system may be used in nuclear plants, Integrated Circuit manufacture, around PLC’s (Programmable Logic Controllers), etc. without concern.

The communication is fully wired and is thus, considered secure.

- Driving Over the Rope

As with any lifeline, driving over the rope should be avoided whenever possible. The effect this will have will depend on the surface the rope is lying on at the time i.e., grass, asphalt, pavement or crushed gravel and the weight of the vehicle driving over it. Sharp stones and gravel easily fray the rope braid and any dirt that is forced into the rope braid may remain inside the rope, even after washing, and will cause abrasion of the rope core later on. Rope lying in grass may just be pushed down into it – but again if the soil is moist or muddy, particles may be forced into the braid. A competent person should always inspect the rope right after a vehicle has driven over the rope.

- Water and Your Communication/Safety Rope

All components of the rope and extension cords have been carefully considered to allow operation in water depths down to 35 feet Water Pressure. Time of operation in water is unlimited.

- ROPE APPLICATION SUMMARY

DO:

- Have a qualified person Inspect the rope before and after every operation

- Store the rope carefully between uses

- Store the rope away from sunlight’s ultraviolet rays, fluorescent light, heat, exhaust fumes, battery acid and fumes, and any other chemical, etc.

- Protect your rope from such hazards as abrasion from sharp edges, rough surfaces

- Shield your rope from heat, open flame and hot debris

- Disinfect or clean the rope in the manner described in this manual (note Part 9.3)

- Keep a record of each rope’s use history

- Keep copies of the product labels and other pertinent information with the rope so that the users can refer to the information

- Replace the rope if the cover of the rope shows damage and/or wear

- Keep separate ropes for Life Safety/Communication applications from those for training

- Immediately destroy* a rope if it has been subjected to impact loads greater than a 0.25 fall factor

- Immediately destroy* a rope that does not pass inspection

- Register your company name with SED Inc. (address noted ref. 2.6) to ensure receipt of updated information or bulletins regarding the product and pertinent to the safe use of the rope.

DO NOT:

- Use the Rescom Combined Safety/Communication™ Rope in a highline system. The load imposed on the rope can be more than ten (10) times the actual load being carried

- Continue use of the rope if it has been subjected to Fall Factors greater than 0.25 as they generate unacceptable impact loads

- Reattach the specialty electrical connectors or install new ones. This must be done by the factory to ensure compliance to the intrinsic safety certification. Failure to do so will void any warranties or guarantees.

When using an Ascender and/or rope grab device, attach to the rope in the manner intended according to the instructions of the manufacturer.

This General Use Rope has a minimum diameter of ½” (13 mm).

NOTE: Please see SED Inc’s policy for re-terminating damaged rope.

- High Temperature Applications

The fibre used in this static kernmantle polyester rope has a melting point of more than 204°C (400°F). However, “thermoplastic materials are not highly resistant to elevated temperatures common during firefighting operations. If this Combined Safety/Communications™ Rope is carried by fire fighters during fire fighting operations, it should be shielded or protected from flame or high temperature exposures” and falling hot debris. “Repeat exposures of the life safety rope to flame or high temperatures can cause degradation of the rope over time and could result in failure during use. Exposure of the life safety rope to flame or high temperatures during use can cause melting” of the rope materials and cause failure.

This rope should only be considered for reuse if at least all of the following conditions are met:

- Rope has not been visually damaged

- Rope has not been exposed to heat, direct flame impingement, or abrasion

- Rope has not been subjected to any impact load

- Rope has not been exposed to liquids, solids, gases, mists, or vapours of any chemical or other chemical or other material that can deteriorate rope

- Rope passes inspection when inspected by a qualified person following the inspection procedures both before and after each use

- Use and Care of the SED Inc Rope

- The rope must be inspected periodically according to the inspection procedure

- Rope must be removed from service and must be destroyed if the rope does not pass inspection or if there is any doubt about the safety or serviceability of the rope

- The rope must be protected from abrasion

- The rope must not be exposed to flame or high temperatures or must be carried in a manner that ensures that it is protected from melting or burning and failure if exposed to the flame or high temperature

- User MUST keep the product label and user instructions/information after they are removed from the rope. Retain this information in the permanent record. You will find an example of this label below:

- Remove the above tag from rope, and retain for your records

- Refer to the user instructions/information before and after each use and log any information required by your organisation

- If the above instructions and information are not followed serious injury can occur

1 NFPA 1983:2017 Edition Appendix A part A.5.1.7 Para.2

2 NFPA 1983:2017 Edition part 3.2.1.2